Font

The size

Interval

Color scheme

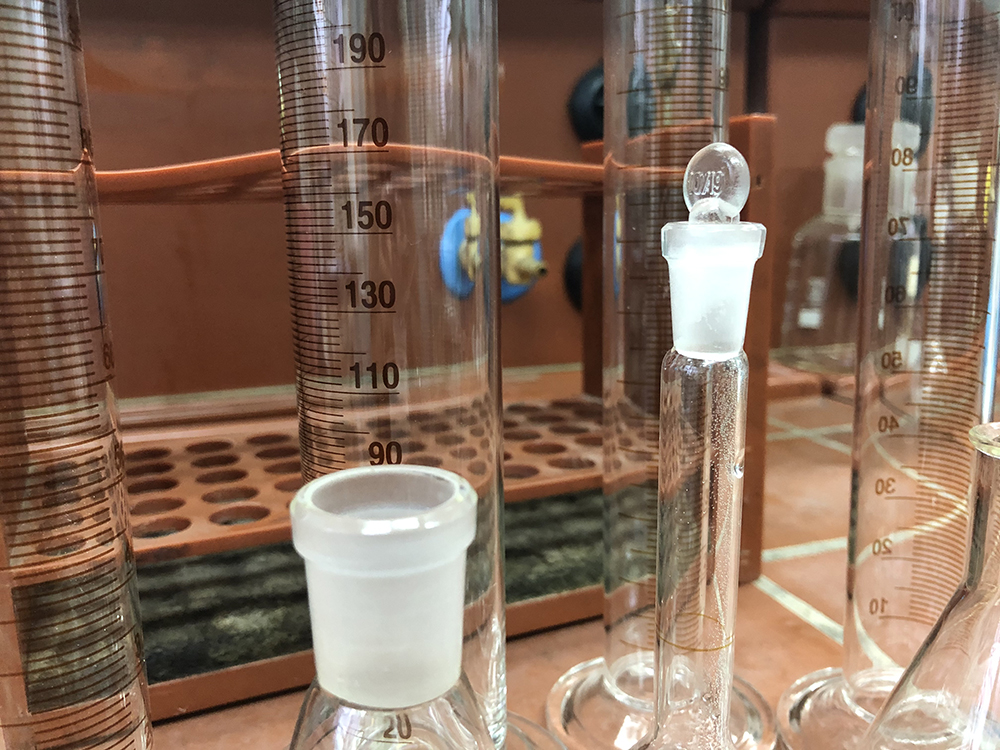

Testing center

The Quality Assurance Service of JSC “Borisov Plastic Products Plant” complies with the criteria of the National Accreditation System of the Republic of Belarus, is accredited for compliance with the requirements of STB ISO/IEC 17025-2007 and is entered in the Register of Accredited Laboratories of the Customs Union under ТR CU 005/2011, ТR CU 007/2011, ТR CU 008/2011.

Test Objects:

- polyethylene pipes and fittings for them: gas pipes, delivery pipes;

- polypropylene pipes and fittings for them: delivery pipes, sewer pipes;

- polyamide pipes;

- polyethylene-coated pipes;

- polyethylene film: single-layer and multi-layer film, shrink film;

- polyethylene bags and sacks, film products;

- plastic parts of general purpose, consumer goods;

- polymer packing;

- canisters for the transport of dangerous goods by road;

- plastic toys;

- plastic consumer goods;

- raw materials: polyethylene, polystyrene, polypropylene and analogues.

Types of tests:

- Physical and mechanical tests:

- tensile strength;

- elongation at failure;

- shrinkage;

- yield point in elongation;

- сresistance of pipes to impact during double-beat bending;

- strength of welding seam;

- resistance to axial loads;

- impact resistance with free falling;

- compressive strength;

- resistance at critical points of molded pieces;

- static coefficient of friction; thermal resistance;

- other types of tests in accordance with the scope of accreditation.

- Hydraulic tests:

- resistance to gas components;

- resistance to constant internal pressure at normal and elevated temperatures;

- leakproofness at constant internal water pressure and negative air pressure of pipe couplings and fittings;

- tear resistance;

- strength at overpressure;

- tightness of tare or sealing tightness.

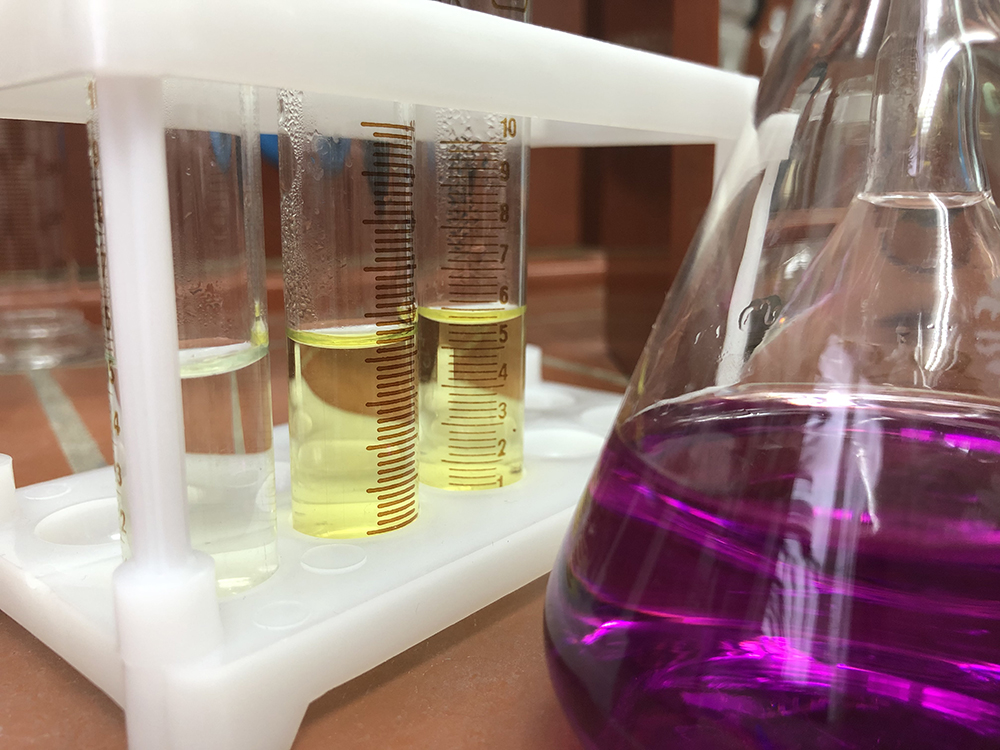

- Hygienic testing of end products:

- the presence of foreign smell and flavor;

- transparency and color of distilled water;

- resistance to hot water;

- chemical resistance and colorant migration;

- resistance to pollution;

- concentration of formaldehyde in an aqueous extract.

- Chemical-analytical tests: determination of harmful substances in the air of the working area.

- Physical factors of the industrial environment: measurements of noise levels, illumination, electrostatic intensity, temperature at workplaces.

- Quality control of polymeric materials: melt flow rate.

- Control of geometric dimensions, capacity and other indicators in accordance with the scope of accreditation.

On the issues of performing testing:

Head of Quality Control Service

Tsyganenko Olga Anatolyevna

tel./fax: +375 (177) 79-08-42

e-mail: skk@bzpi.by

The Quality Assurance Service of JSC “Borisov Plastic Products Plant” complies with the criteria of the National Accreditation System of the Republic of Belarus, is accredited for compliance with the requirements of STB ISO/IEC 17025-2007 and is entered in the Register of Accredited Laboratories of the Customs Union under ТR CU 005/2011, ТR CU 007/2011, ТR CU 008/2011.

Test Objects:

- polyethylene pipes and fittings for them: gas pipes, delivery pipes;

- polypropylene pipes and fittings for them: delivery pipes, sewer pipes;

- polyamide pipes;

- polyethylene-coated pipes;

- polyethylene film: single-layer and multi-layer film, shrink film;

- polyethylene bags and sacks, film products;

- plastic parts of general purpose, consumer goods;

- polymer packing;

- canisters for the transport of dangerous goods by road;

- plastic toys;

- plastic consumer goods;

- raw materials: polyethylene, polystyrene, polypropylene and analogues.

Types of tests:

- Physical and mechanical tests:

- tensile strength;

- elongation at failure;

- shrinkage;

- yield point in elongation;

- сresistance of pipes to impact during double-beat bending;

- strength of welding seam;

- resistance to axial loads;

- impact resistance with free falling;

- compressive strength;

- resistance at critical points of molded pieces;

- static coefficient of friction; thermal resistance;

- other types of tests in accordance with the scope of accreditation.

- Hydraulic tests:

- resistance to gas components;

- resistance to constant internal pressure at normal and elevated temperatures;

- leakproofness at constant internal water pressure and negative air pressure of pipe couplings and fittings;

- tear resistance;

- strength at overpressure;

- tightness of tare or sealing tightness.

- Hygienic testing of end products:

- the presence of foreign smell and flavor;

- transparency and color of distilled water;

- resistance to hot water;

- chemical resistance and colorant migration;

- resistance to pollution;

- concentration of formaldehyde in an aqueous extract.

- Chemical-analytical tests: determination of harmful substances in the air of the working area.

- Physical factors of the industrial environment: measurements of noise levels, illumination, electrostatic intensity, temperature at workplaces.

- Quality control of polymeric materials: melt flow rate.

- Control of geometric dimensions, capacity and other indicators in accordance with the scope of accreditation.

On the issues of performing testing:

Head of Quality Control Service

Tsyganenko Olga Anatolyevna

tel./fax: +375 (177) 79-08-42

e-mail: skk@bzpi.by